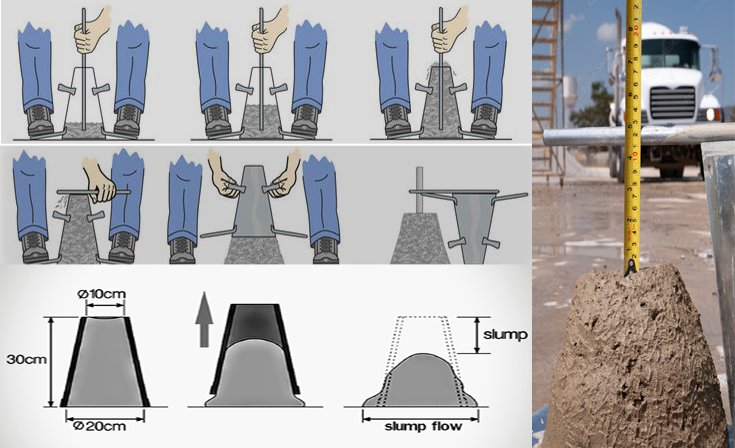

Concrete curing is the most important factor for the development of strength and attainment of durability in concrete as well as reduction in the risk of failure due to other causes like cracking, etc. Concrete curing is, therefore, the process of maintaining adequate moisture and temperature in freshly placed concrete to ensure hydration continues for some specified time duration; it is in the course of hydration that cement reacts with water to form the hardened binder that eventually imparts strength to concrete. By far, the best concrete curing practices will ensure your slabs, foundations, and all other concrete structures will last long.

Why is Concrete Curing So Important?

The following are a few of the important performance characteristics of concrete that are directly related to proper curing:

- Increased Strength and Durability: Good curing helps the concrete reach its ultimate strength potential and thereby makes it more resistant to wear, abrasion, and impact.

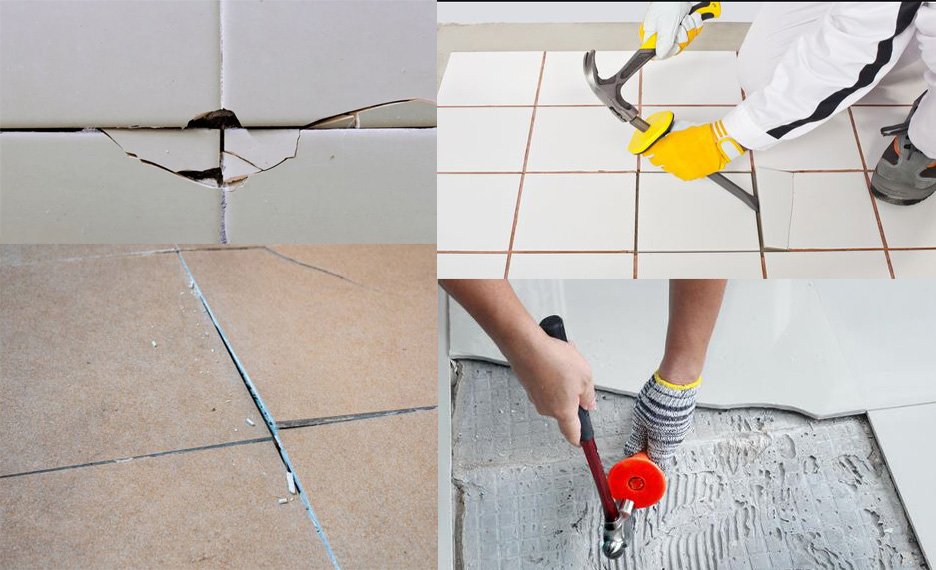

- Reduced Shrinkage Cracking: Shrinkage cracking reduces due to curing, reducing the loss of moisture, which is the primary factor causing shrinkage cracks. These cracks are very detrimental to the strength of a structure and may also affect its appearance.

- Improved Freeze-Thaw Resistance: For warmer climates, the cured concrete resists much better damage from freeze-thaw cycles.

- Enhanced Water Resistance: Dusting is reduced through proper hydration, which has a positive effect on the appearance and performance of concrete surfaces.

- Dusting Resistance: Dust is resistant to surface spalling if hydrating is ample; it keeps the looks and performances up for concrete.

Best Practices for Concrete Curing:

- Water Curing: This is, by far, the most effective method as it keeps the concrete surface in continuous moisture. It can be affected by ponding, continuous sprinkling, or soaker hoses.

- Moisture Retaining Methods: This covers the concrete surface with wet burlap, cotton mats, or water-proof paper to prevent the evaporation of moisture. These materials must continue to remain wet throughout the period of curing.

- Membrane Forming Compounds: These liquid compounds are poured or sprayed onto the concrete surface at their respective viscosities, after which a film of a certain thickness is formed. They seal in the moisture. Most applicable in arid hot weather conditions, where water evaporation is extremely high.

- Internal Curing: A development in which special admixtures hold internal moisture and decrease dependability on an outside cure. Most advantageous for large pour.

- Steam Curing: An accelerated curing method in which concrete is exposed to high-temperature steam to precast production in a controlled environment house.

Factors That Affect Accelerated Curing Time

Several factors influence the required curing time:

- Cement Type: Different types of cement hydrate at different rates.

- Ambient Temperature and Humidity: Conducive temperatures normally would require a shorter accelerated curing period. However, low temperatures with high humidity can lengthen the period.

- Concrete Mix Design: The water-cement ratio and the use of supplementary cementitious materials play a big role in effecting curing time by influencing the hydration process.

- Desired Strength: Concrete that has not been cured properly tends to readily reach desired strength levels.

Frequently Asked Questions (FAQ):

Q: How long should concrete be cured?

A: As a general rule, concrete should be cured for a minimum of 7 days. However, the specific curing time depends on the factors mentioned above. Consult with a concrete professional or engineer for specific recommendations.

Q: What will happen if the concrete is not properly cured?

A: Improper curing is the most common hazard for this concrete after its use in the built environment. It will result in low strength, high shrinkage cracking, low durability, and high permeability to the surface.

Q: Which is the best curing method for hot weather?

A: In hot weather, evaporation rates are high. Using moisture-retaining methods like wet burlap or membrane-forming compounds is recommended.

Q: Can I use plastic sheeting for curing?

A: Plastic sheeting will stop moisture evaporation. However, it will also trap heat, which harms the concrete. If you use plastic, make sure it is white to avoid heat absorption due to insulation from sunlight and not in direct contact with the concrete surface. An inch of wet burlap underneath helps a lot.

Q: How can I tell if the concrete is properly cured?

A: While a visual inspection can help identify surface defects, concrete strength testing is the most reliable method for determining proper curing.

Read More: Comprehensive Guide to Testing Construction Materials ensuring quality and safety

Conclusion:

Proper concrete curing is one step further to long-lasting and sturdy concrete structures. If you are aware of the different curing processes and influencing factors, you can surely make your concrete projects work for what they are meant for. Seek expert advice regarding the best curing practice for your project to seal in sure investments for your concrete works.