Description

Introduction to Combined Footings

Combined footings are a crucial element in civil engineering design, representing a structural solution employed when building loads necessitate a unified footing to support multiple columns or walls. Rather than providing individual footings for each structural element, combined footings distribute loads from these elements across a larger area of soil. This design minimizes localized stresses and is essential in situations where soil-bearing capacity is limited or when adjoining footings would overlap, potentially compromising structural integrity.

The primary purposes of combined footings include enhancing load distribution and ensuring stability in the presence of eccentric loads. In cases where columns are positioned closely together, the breadth of individual footings may not be feasible. Here, combined footings serve the vital function of spreading the load over a wider area, thus preventing excessive settlement and ensuring that all structural components work harmoniously. This is particularly relevant in urban environments where space is often at a premium.

Unlike individual footings that support a single column, combined footings engage multiple support locations, allowing for a more efficient use of materials and resources. Depending on site conditions and design requirements, they can take various forms, including strap footings, slab footings, and mat footings. Several factors, including load magnitude, soil properties, and the proximity of neighboring structures, guide selecting the appropriate footing type.

The ACI 318 code provides essential guidelines for the design and construction of combined footings, offering engineers standardized approaches to ensure safety, stability, and performance. Adhering to this code is fundamental, as it encapsulates best practices and scientific principles that underpin effective footing design. Understanding the intricacies of combined footings and their significance is integral for engineers tasked with project execution in civil construction.

Overview of ACI 318 Requirements

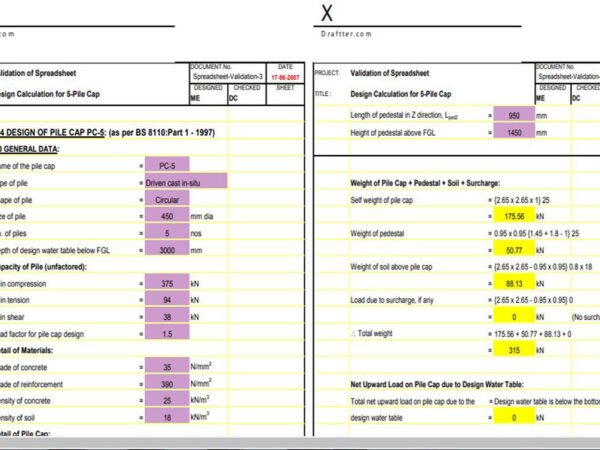

The American Concrete Institute (ACI) 318 provides comprehensive guidelines and standards for structural concrete design and construction, including specific provisions for combined footing design. Among the prominent features outlined in ACI 318 are the criteria for material properties, design loads, and structural integrity, which are vital in ensuring the safety and stability of combined footings. One of the central directives in ACI 318 is the adherence to minimum material strength requirements. For example, concrete used in combined footings should typically meet a specified compressive strength, while reinforcing steel must comply with standard yield strength values. This ensures that the footing can withstand the applied loads throughout its service life.

Load considerations form a critical part of the design specifications put forth in ACI 318. The standard emphasizes the need to calculate both the dead loads and live loads accurately, incorporating factors that account for varied conditions such as settlement or eccentric loading. Understanding these load considerations is essential for engineers, as they directly influence the footing’s sizing and reinforcement detailing. Additionally, ACI 318 requires the evaluation of special loading scenarios, such as seismic and wind loads, which can significantly impact the design process.

Engineers must also pay close attention to the safety factors specified in ACI 318. The standard outlines the necessary load combinations and related safety factors that should be applied during design to ensure adequate performance under maximum expected loads. Sections related to durability enhancements, deflection limitations, and cracking control are equally crucial, providing further specifications that help maintain structural integrity. By familiarizing themselves with the key sections of ACI 318, engineers can effectively navigate the complexities of combined footing design, ensuring that their designs not only meet regulatory requirements but also embrace safety and performance standards essential in the construction industry.

Creating an Excel Sheet for Combined footing Design Design Calculations

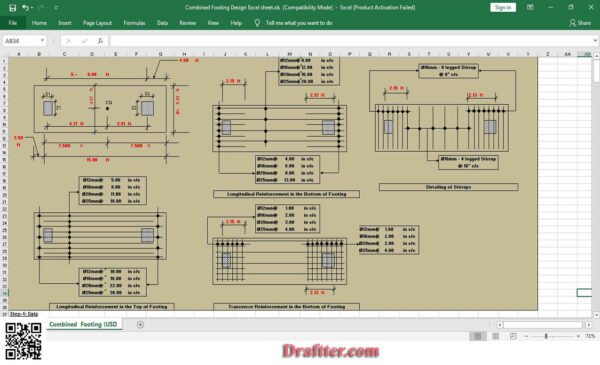

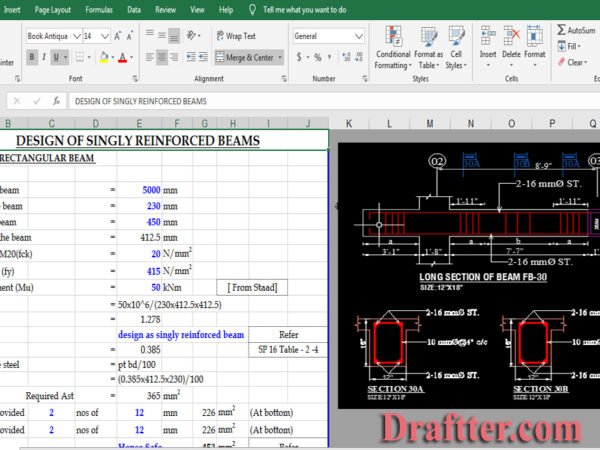

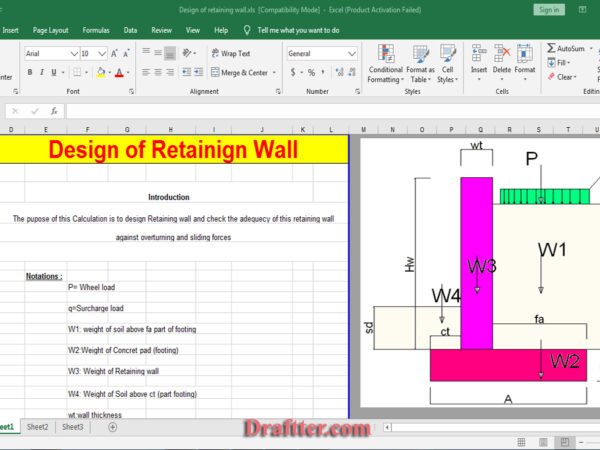

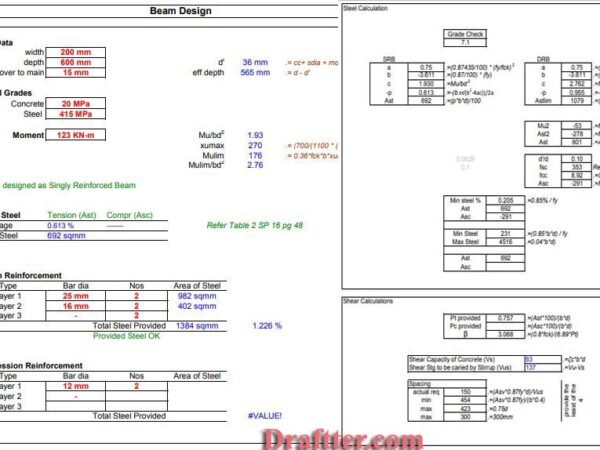

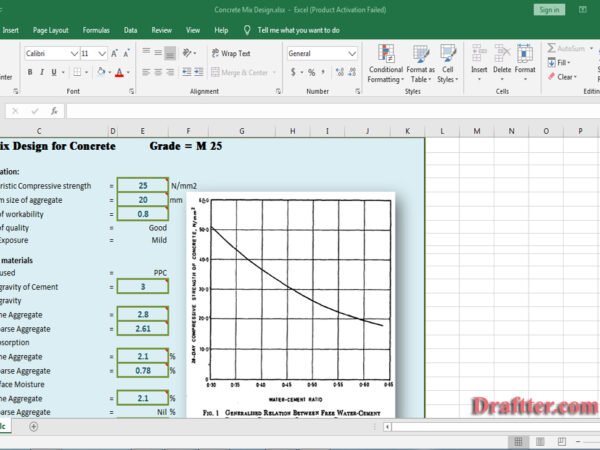

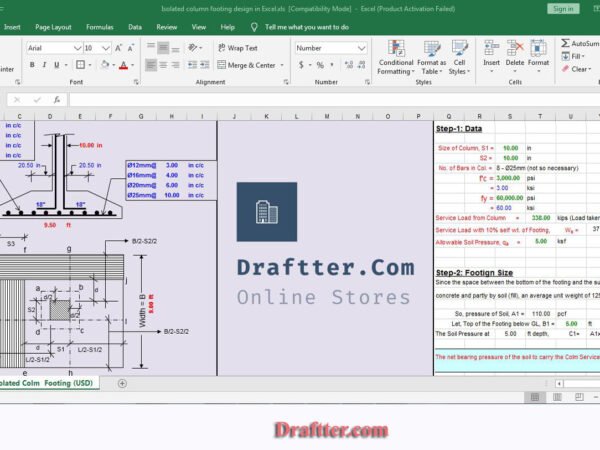

Creating an Excel sheet for combined footing design calculations can enhance accuracy and efficiency in structural engineering. The first step involves opening a new Excel workbook and preparing the layout to accommodate various input parameters and outputs. It is advisable to organize the sheet into distinct sections: the header, input parameters, calculation formulas, and results.

In the header, you may include the project title, date, and designer’s details. Next, define the input parameters necessary for the combined footing design. This includes inputting load data such as axial loads, moments, and lateral loads, as well as material properties like concrete strength and reinforcement details. To improve user experience, it is essential to structure these inputs in a clear, concise manner, ideally labeled and grouped logically.

Once the input parameters are established, you can proceed to enter the necessary formulas that govern combined footing design according to ACI 318 standards. Key calculations should involve checking bearing capacities, shear, and bending moment evaluations. Utilizing Excel’s built-in formula functions will allow for a dynamic interaction with the entered data; any alterations in input will automatically update the results. For instance, the use of summation and multiplication functions will facilitate the computation of resultant loads.

To further enhance clarity, including screenshots or visual aids of the form and formulas can be beneficial, especially for those less familiar with the soft wares. Finally, conducting an example calculation will illustrate the various components of the Excel sheet in action. For instance, using hypothetical load values to demonstrate the computed outputs instills confidence in the effectiveness of your spreadsheet for combined footing design calculations. This practical application ultimately showcases the power of Excel in engineering analyses.

Performing Structural Analysis with the Excel Sheet

Utilizing an Excel sheet for combined footing design analysis in accordance with ACI 318 can greatly streamline the structural evaluation process. By inputting the appropriate parameters into the pre-designed spreadsheet, engineers can efficiently analyze various loads and ensure compliance with specified standards. The first step in this process involves entering the key data, such as the size of the footing, the dimensions of the columns, and the applied loads, including dead and live loads.

Once all necessary parameters are accurately entered into the Excel sheet, the analysis can be performed using the built-in formulas which reflect the guidelines set forth in ACI 318. These formulas will calculate critical design criteria, such as soil bearing capacity, bending moments, and shear forces. It is essential to verify the output results to establish whether the combined footing can safely support the applied loads without exceeding the materials’ allowable stress limits.

For example, if the calculated soil bearing pressure exceeds the allowable limit, adjustments to the footing dimensions may be required. The Excel sheet allows for quick modifications, enabling engineers to assess multiple scenarios. Additionally, understanding the output results is crucial; for instance, the moments and forces calculated will help in determining the reinforcement requirements for the footing. It is advisable to maintain clear documentation of any changes made during the analysis process.

Common errors may arise during the analysis phase, often due to incorrect data entry or misunderstanding of the output results. To mitigate such issues, double-checking each input value is recommended. Excel’s built-in error-checking features can also help identify problematic calculations. Should discrepancies occur, reviewing the parameters or consulting the ACI 318 guidelines can clarify the intended design approach. With thorough attention to detail, the structural analysis process becomes a structured, reliable method for ensuring sound footing design.

Case Studies and Practical Applications

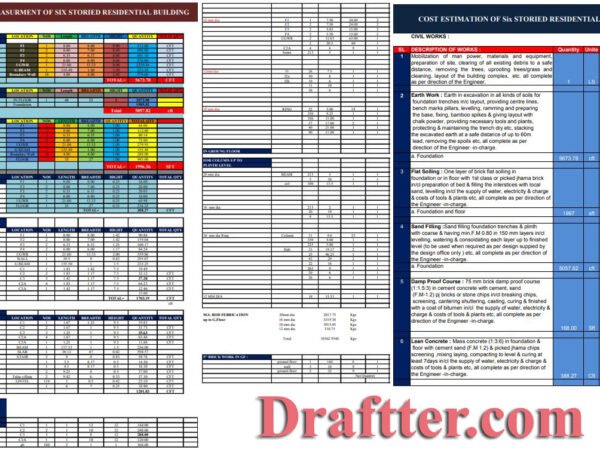

The practical application of combined footing design calculations using Excel, guided by ACI 318 standards, is crucial in ensuring structural integrity in various engineering projects. To illustrate this, several real-world case studies showcase the versatility of combined footings in addressing complex site conditions and load considerations.

One notable case involved a multi-story commercial building situated on a site with weak soil conditions. Engineers opted for a combined footing to distribute the building’s loads effectively. By employing an Excel sheet tailored for combined footing design calculations, they ensured precise load distributions and immediate adjustments in the design process when facing unforeseen challenges, such as variations in soil bearing capacity. The calculated reinforcement areas were adjusted efficiently, demonstrating how Excel can present real-time data modifications, which is invaluable for project timelines.

Another example is a residential complex constructed in an area with multiple adjacent structures. The use of combined footings became essential to mitigate differential settlement risks. Engineers utilized the ACI 318 guidelines integrated into an Excel spreadsheet to calculate necessary dimensions, reinforcement details, and environmental factors. The challenges encountered included accommodating existing infrastructures while adhering to local building codes. The Excel calculations facilitated quick assessments and comparisons of various design alternatives, ultimately leading to a robust solution that optimized both structural capability and cost-effectiveness.

From these case studies, several lessons emerged. First, the integration of Excel in the design process significantly reduces time spent on calculations, allowing engineers to focus on critical design aspects. Additionally, direct access to ACI 318 provisions within the Excel framework ensured compliance. These practical applications highlight the importance of technological tools like Excel in structural engineering, particularly for combined footings, as they enable engineers to overcome challenges creatively and efficiently.

Reviews

There are no reviews yet.